The case for switching from traditional soluble anodes to modern insoluble anodes has never been stronger. With regulatory requirements discouraging hexavalent chrome processes, and the challenges of soluble anodes on a system, now is the time to consider switching to dimensionally stable insoluble BADGERCHROME mixed metal oxide anodes.

As an insoluble anode BADGERCHROME anodes add almost zero impurities to the electrolyte. Contrasting with lead and graphite anodes where operators need to closely monitor hazardous substances such lead chromate and lead oxide. Our clean running anodes make monitoring a micro-tuning process rather than a macro-tuning one.

As a dimensionally stable anode, BADGERCHROME anodes keep their shape regardless of usage duration. Anodes that dissolve over time require constant voltage adjustments to match anode current surface area to electroplating requirements. As a traditional anode dissolves, the product quality has constant creep downward in the ever changing system. BADGERCHROME anodes maintain a constant inter-electrode gap right up to the very end of anode life.

The final and perhaps the most beneficial feature of BADGERCHROME Mixed Metal Oxide anodes is we have the capabilities to refurbish any anode we have made. Where soluble anodes typically exceed their useful life relatively quickly compared to weight, BADGERCHROME anodes utilize a reusable titanium framework. After a cleaning and recoating process, BADGERCHROME anodes are ready for their second and third life, greatly reducing the lifetime cost of the anode.

- Constant voltage through anode life

- Predictable end product quality

- Proven lower anodic operating potentials

- Increased energy savings through uniform current distribution

- Increased flexibility in shapes and sizes for better coverage

- High mechanical stability

- High thermal stability

- No breakdown product buildup

- Recovery and replating services

Custom BADGERCHROME Design Parameters to consider

- Base Material: Grade 1 Titanium

- Coatings: Iridium, platinum, and other mixed metal oxide as required

- Coating Thickness: 0.1 µm to several hundred µm

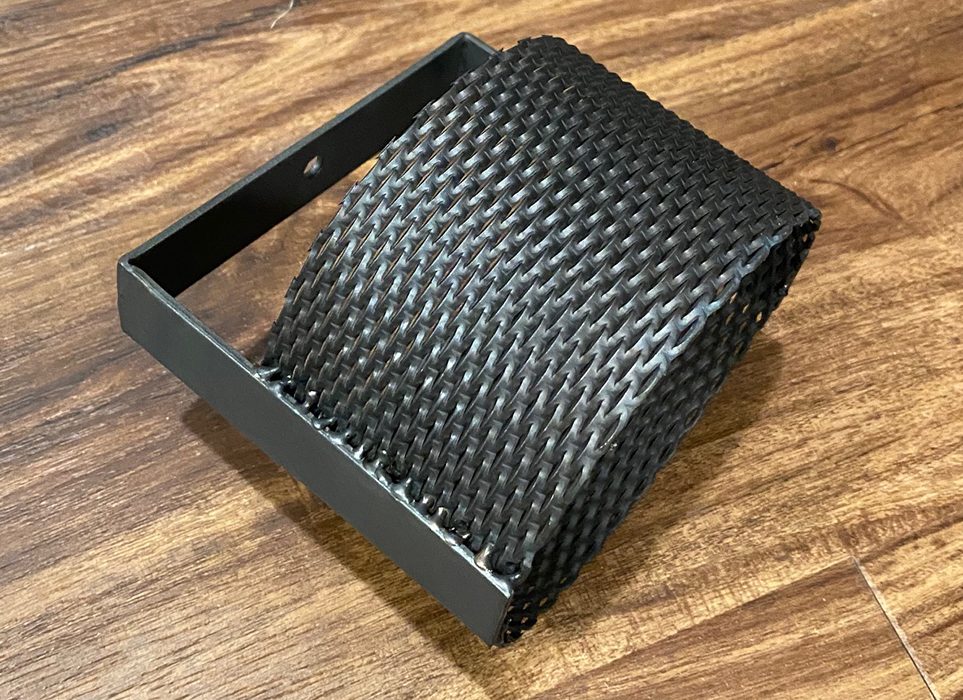

- Shape: Mesh, plates, sheet, tubes, rod, customized

- Operating life: 3 years or per your specification

Common Applications

- Electro galvanizing (zinc plating), including steel strip plating

- Precious metal plating

- Trivalent chrome plating

- Hard chromium plating

- Copper plating, copper foil production and copper foil treatment

- PCB copper plating

As precious metals become more and more difficult to mine with large deposits being largely exhausted via traditional mining methods, every gram of metal needs to be recovered. Let BADGERCHROME Mixed Metal Oxide anodes help you leave nothing behind.

Electrowinning or electroextraction is a purification process that puts a metal ore into a solution and using electrodeposition to remove the pure metal from the solution – what is commonly known as leaching. This is a very economical process for purification of non-ferrous metals. The historical anode of choice for electrowinning is lead dioxide. While this anode type works well enough, the advantages of BADGERCHROME mixed metal oxide (MMO) far outweighs the learning curve for this advanced process. By utilizing BADGERCHROME anodes, you will reduce your energy consumption (and normalize it), reduce lead waste, increase shape options, and reduce environmental pollution. The choice is clear BADGERCHROME anodes will show real changes to your yields both financially and physically.

American Carbon Company has experience designing anodes for electrowinning applications of nickel, zinc, cobalt, and copper as well as precious metals such as gold, silver, platinum metal group metals, and cadmium.

BADGERCHROME anodes are the premier option for all electrorefining and electrorecovery operations. Contact us today to start designing the perfect anode for your application.

- Constant voltage through anode life

- Predictable end product quality

- Proven lower anodic operating potentials

- Increased energy savings through uniform current distribution

- Increased flexibility in shapes and sizes for better yields

- High mechanical stability

- High thermal stability

- No breakdown product buildup

- Increased yields due to fewer impurities

Custom BADGERCHROME Design Parameters to consider

- Base Material: Grade 1 Titanium

- Coating: Ruthenium oxide, Iridium, tantalum, and platinum

- Electrode Shape: Square, rectangle, circle, plate, strip expanded mesh, corrugated, perforated wire, rods, tubes, discs, or any other shape

- Current Density: 350-500A/m2

Common Applications

- Non-ferrous metal extraction (copper, zinc, nickel, cobalt)

- Precious metal extraction (gold, silver, platinum metal group)

- Precious metal recovery (copper, precious metals, other valuable metals)

As one of our most limited, but also most overlooked resources, clean fresh water is one of the most critical natural resources we have. One of the largest untapped sources of fresh water covers nearly 70% of the earth’s surface – our oceans. While we didn’t invent the technique of electrochlorination, we have refined it such that it is a cost effective and reasonable solution to producing water that is not only safe for human consumption and use, but also reduces the wear and corrosion on systems that use water for cooling. Learn more about how BADGERCHROME anodes assist in hypochlorite production.

By using low voltage DC current through an electrolyzer cell, the saltwater is electrolyzed and produces sodium hypochlorite and hydrogen gas. Sodium hypochlorite provides a chlorinated system that effectively disinfects the water. From a forward looking perspective, the production of hydrogen is looked at as an energy source of the future. Picture coasts around the world, both producing clean, safe drinking water AND clean sustainable energy through the same process. This symbiotic system will be the future and we are proud to be on the forefront of this technology.

BADGERCHROME anodes are the premier option for all water treatment operations. Contact us today to start designing the perfect anode for your application or form a partnership for your research and development of new processes and technologies.

BADGERCHROME WATER TECHNOLOGIES

- Constant voltage through anode life

- Predictable end product quality

- Proven lower anodic operating potentials

- Increased energy savings through uniform current distribution

- Increased flexibility in shapes and sizes for increased throughput

- High mechanical stability

- High thermal stability

- No breakdown product buildup

- Less chemical intense process compared to traditional solutions

Custom BADGERCHROME Design Parameters to consider

- Base Material: Grade 1 Titanium

- Coating: Ruthenium oxide, Iridium, tantalum, and platinum

- Electrode Shape: Square, rectangle, circle, plate, strip expanded mesh, corrugated, perforated wire, rods, tubes, discs, or any other shape really that you can dream up

- Complete system design options for turn key solutions

Common Applications

- Aquatics and pools

- Potable water treatment

- Wastewater treatment

- Odor and corrosion control

- Water clarification

ABOUT US

Founded in 1998 to support specifically the Cathodic Protection and Specialty Graphite Industries, American Carbon Company continued building upon management’s many years of experience in sourcing and developing new product lines. With extensive experience in specialty graphite products, the transition to providing graphite anodes to the Cathodic Protection industry was quite natural. The expansion into this industry lead to our development of all bare anode lines, and our continued growth in the Specialty Graphite Industry.

Our experiences in corrosion prevention vastly expanded our material science expertise and we now service many industries with materials to make existing products better through higher corrosion resistance, lighter weight, or greater strength. Our primary focus is on non-ferrous metals and carbon based products and additives (including synthetic graphite, titanium, magnesium, and graphene). Our raw and semi-finished products are leading the way to a more efficient, cleaner world.

We are always exploring new opportunities to provide high quality products to our customers. If you are looking for a difficult to find product look no further, American Carbon has a long track record for solving problems brought to us by the customer. Our sourcing and manufacturing capabilities ensure we are versatile in a changing industry.

American Carbon is a family business with family values. Customer service is the cornerstone to our business.